Table of Contents

Laser Operations

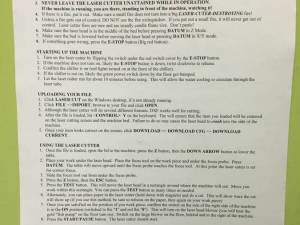

If you like the “how-to” small posters on the laser cutter room walls, you can download that PDF here.

Operating the laser is a rewarding experience, however it takes patience and training in order to do so safely and effectively. The guide below is intended to be a supportive utility beyond the required training to operate the equipment. Laser operation generally consists of preparing the material, preparing your cut on the computer using a CAD/CAM software toolchain, and finally, preparing and operating the laser cutting machine.

Before doing anything, read all of the posted safety and operational signage.

Material Preparation

Acceptable Materials

Approved materials are:

- non-treated woods

- acrylic

- cardboard

- paper

- glass (engraving/frosting only)

You are welcome to cut materials 3/8“ or thinner. 3/8” is “thick” for our laser. Feel free to touch base with the trainers if you are interested in cutting thicker materials.

Some not Explicitly approved materials, but have been tested to be ok, check with the laser officer before doing more than small samples of these.

- Speedball Speedy-Cut-Easy (the easy is important, non easy has pvc in it), other hackerspaces/laser users have reported using it fine

- Ingredients COMPOSITION / INFORMATION ON INGREDIENTS

Blend of paraphinic plasticizer, calcium carbonate, titanium dioxide, styrene butadiene styrene synthetic

rubber, white factis synthetic rubber, polysiloxane, magnesium stearate, calcium stearate. - It is a bit stinky.

- 3M™ Scotchlite™ Reflective tape, still unknown on composition of backing, but the tape itself is acrylic and the reflective stuff does not hurt the cutter, but does need to be masked with tape for good /clean cutting

Disallowed materials are:

- plastics prefixed with “poly”, e.g. PVC.

- treated woods

There may be exceptions. Again, talk to one of the laser trainers first.

Material Constraints

The laser operates on a 900mm x 600mm table. We don't recommend exceeding 800mm x 500mm1) in your design. Your material should be very flat. A non-flat material will result in imperfect cuts, both in desired shape and inability to punch your design out of the material blank.

CAD & CAM Operation

Designing Your Cut Files

Most vector drawing applications will be able to export into .dxf, the output file needed for our CAM program. Typical programs to draw your cut in are:

- Inkscape (free, open-source)

- Adobe Illustrator

- AutoCAD

- Creo/ProE/SolidWorks/Rhino

We use Inkscape, and have it ready on our machine. How to use Inkscape to generate “paths” will not be covered here.

Some members use Sketchup for their design work, instead of Inkscape. You must have a dxf export plugin to enable .DXF export. That plugin is verified to work with Sketchup 82) , unknown if it works with newer versions.